1. Objective

The objective of this stage is to apply and integrate advanced part modeling and assembly techniques in SolidWorks—including Swept, Lofted, Shell, Rib, Wrap, Pattern, Assembly, and Drawing tools—to design, assemble, and document a complete 3D model of a portable water purifier. This stage aims to achieve both functional precision and professional presentation under the guidance of our supervising teacher.

2. Summary of Learning

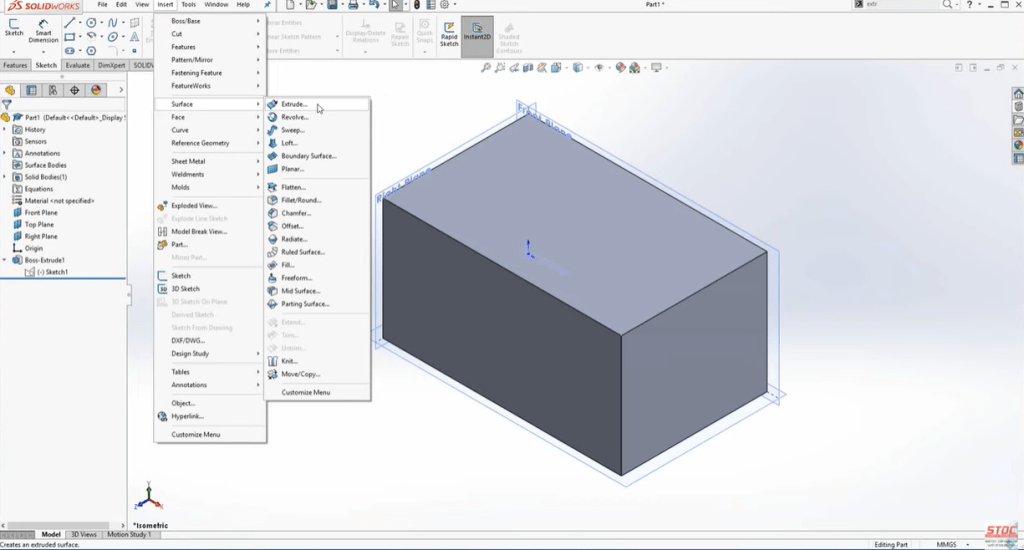

Throughout this research stage, our team explored a range of advanced modeling and assembly features in SolidWorks.

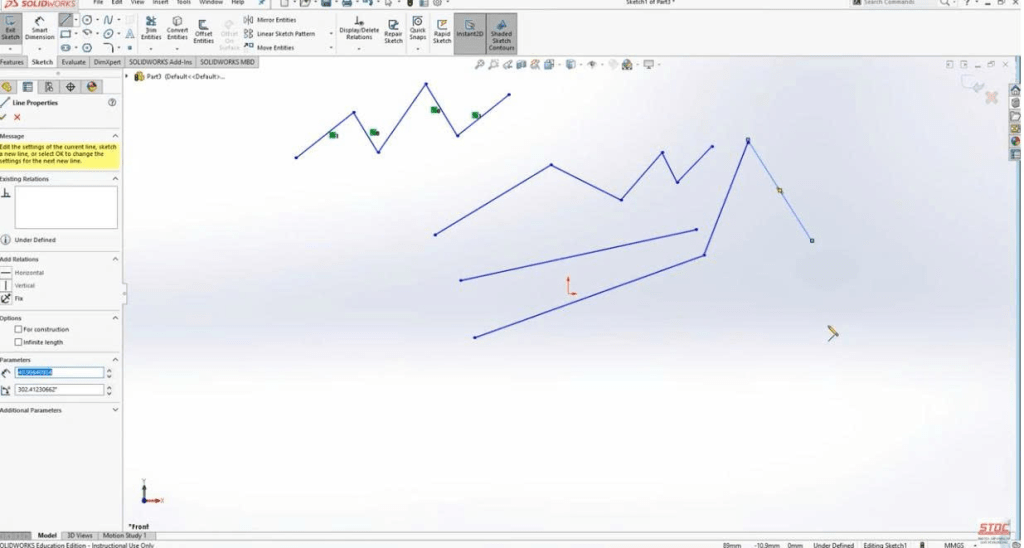

- The Swept and Lofted commands were used to create complex geometries with smooth transitions and varying cross-sections, which are essential for designing curved connectors and streamlined fluid paths.

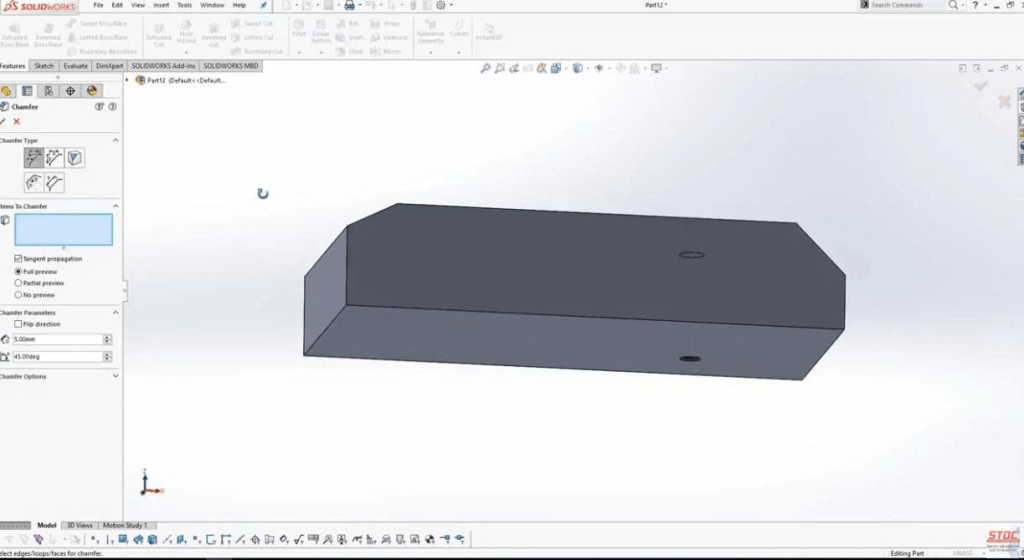

- The Shell and Rib tools helped reduce material usage while maintaining structural strength, allowing us to design lightweight yet durable housings.

- The Wrap feature was applied to project sketches onto curved surfaces, enabling the creation of engraved logos and decorative labels.

- Pattern tools (Linear and Circular) were used to efficiently replicate repeated elements such as holes, fins, and ribs, ensuring symmetry and design consistency.

In the Assembly environment, we practiced combining all designed components using mates such as coincident, concentric, and distance to ensure precise alignment and realistic motion. Finally, in the Drawing module, our team generated 2D technical drawings from the 3D models, including dimensions, annotations, and exploded views for manufacturing documentation and presentation purposes.

3. Application to Water Purifier Design

Each advanced modeling tool was systematically applied to the portable purifier design.

- Swept and Lofted features were utilized for internal flow tubes and filter housings.

- Shell and Rib improved the casing’s strength-to-weight ratio and reinforced thin-walled structures.

- Wrap added engraved labeling and aesthetic detailing, while Pattern commands allowed efficient duplication of holes, vents, and screws.

During the Assembly stage, all parts were precisely aligned and mated to form a complete prototype, ensuring smooth fit and interaction between the filters, connecting pipes, and outer frame. The Drawing environment provided professional 2D blueprints with full dimensions, annotations, and exploded views, serving as essential documentation for real-world manufacturing and assembly.

4. Conclusion

By mastering advanced modeling, assembly, and documentation tools, our team successfully created a detailed, manufacturable 3D prototype of the portable water purifier. The integration of part modeling, mechanical assembly, and engineering drawing not only enhanced technical accuracy but also reflected professional standards in product design and presentation. This stage represents a major milestone in the Eco Filter Project, demonstrating the team’s ability to move from concept to near-production readiness.

5. Next Step

The next research phase will focus on Rendering and Simulation in SolidWorks.

→ Our team will analyze fluid flow, evaluate structural strength, and create realistic visual renderings of the water purifier to assess both functional performance and presentation quality before prototype fabrication.