Electronic Circuit Design Fundamentals in Altium Designer: Installation, Workspace Setup, and Library Configuration

- Objective

The objective of this stage is to develop a foundational understanding of electronic circuit design using Altium Designer. This part focuses on installing the software, setting up component libraries, and learning essential operations and shortcuts for managing schematic projects efficiently.

Our team aims to build a complete and functional design environment for developing the electronic control system of the Water Purifier Project, under the guidance of our instructor.

- Summary of Learning

During this phase, our team learned how to download, install, and activate Altium Designer. We practiced configuring the workspace to create a comfortable and efficient working environment. We also installed and organized component libraries, which provide access to common electronic parts such as resistors, capacitors, diodes, and integrated circuits (ICs).

Through the introductory practice (P1), we explored the user interface, identified key design panels, and used keyboard shortcuts to improve design efficiency. We also learned how to create new schematic projects, name and organize files systematically, and prepare folders for future PCB development.

These experiences gave the team a clear understanding of the software structure, workflow for project creation, and the importance of proper library configuration in electronic design.

- Application to Water Purifier Project

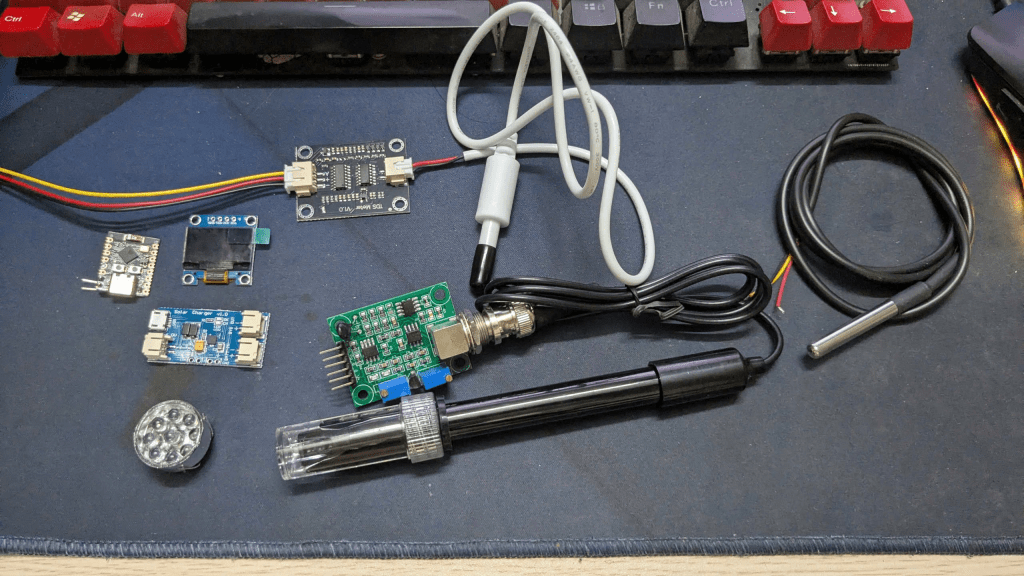

In the Water Purifier Project, our team applied these skills to set up the electronic control system design environment.

We installed and configured component libraries for the project’s sensor modules, microcontroller, and power management circuits. Then, we created a dedicated Altium project for the purifier’s control board, ensuring clear folder organization for both schematic and PCB files.

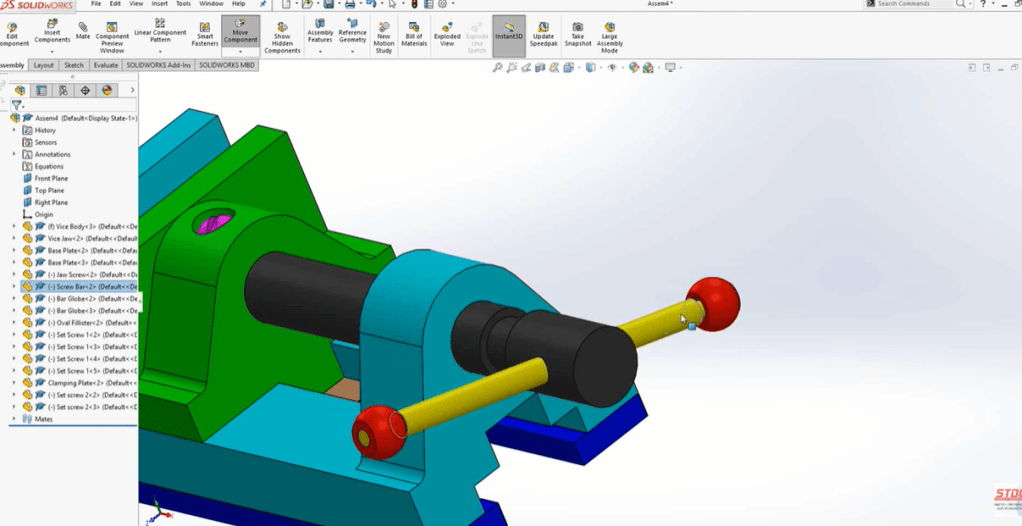

This preparation ensures that all future circuit designs will be consistent, accurate, and ready for integration with the mechanical structure previously modeled in SolidWorks.

- Conclusion

This stage provided our team with a strong foundation in using Altium Designer. We gained confidence in installing the software, customizing the workspace, and managing libraries — essential skills for professional PCB design.

The knowledge from this phase effectively bridges the gap between the mechanical design phase (SolidWorks) and the electronic design phase (Altium Designer) of the Water Purifier Project, enabling smooth integration in the final prototype.

- Next Step

In the next stage, our team will begin schematic drawing and circuit design, connecting sensors, control units, and power components. This marks the first step toward building the functional electronic system of the Water Purifier, preparing for PCB layout and full system integration.