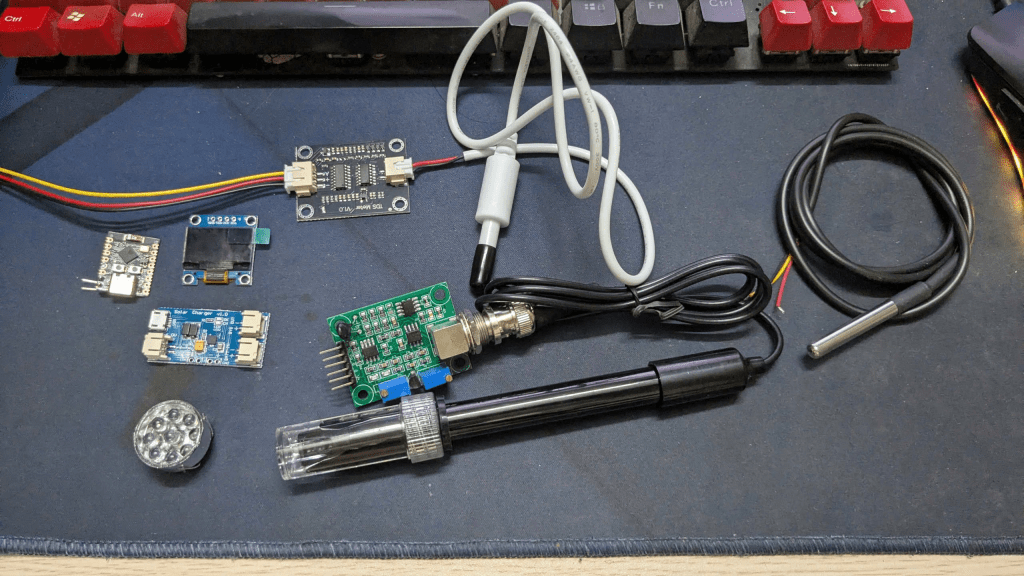

Despite completing the full PCB design workflow in Altium Designer, the final implementation of the Water Purifier control circuit did not achieve the intended functionality. During the testing phase, the circuit failed to maintain stable voltage and current levels required for the purification modules, resulting in incomplete filtration. The output water remained impure and unsafe for use, indicating that the electronic control system was not effectively regulating the purification process.

The main source of failure was traced to insufficient power management and grounding design. Electrical noise interfered with sensor readings and relay operations, causing unstable control signals and irregular pump activation. As a result, the filtration cycle was frequently interrupted, and the purifier could not sustain the necessary operating conditions for proper water treatment.

Additionally, the PCB layout lacked adequate decoupling and shielding, leading to voltage drops across key components. This design flaw, combined with inaccurate sensor calibration, prevented the system from responding accurately to water quality feedback. Even though the schematic and routing were technically valid, the real-world performance exposed critical weaknesses in electrical reliability and system integration.

This failure demonstrated that correct circuit design on software alone does not guarantee functional success in hardware. The team recognized the importance of validating design assumptions, simulating real load conditions, and performing detailed power integrity analysis before production. Although the project did not meet its practical goal, it provided valuable lessons in identifying and understanding failure mechanisms in PCB-based control systems.