1. Objective

The objective of this research stage is to develop comprehensive skills in assembling 3D mechanical components and producing technical assembly drawings in SolidWorks. This study, conducted under the guidance of our supervising teacher, focuses on applying both basic and advanced Mate features to enhance mechanical precision, simulate realistic motion between parts, and generate professional 2D documentation for manufacturing and analysis.

2. Summary of Learning

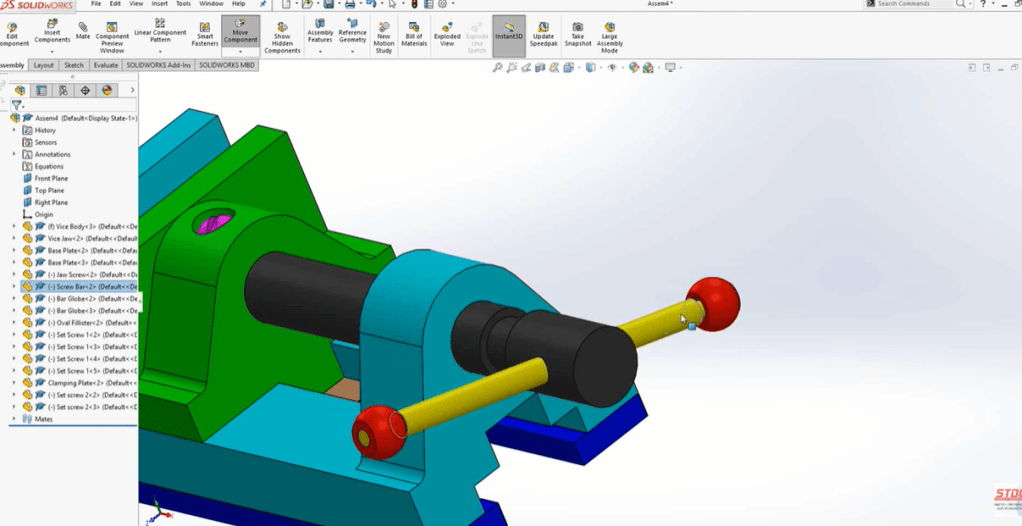

Throughout this stage, our team gained a solid understanding of the complete assembly workflow in SolidWorks.

- Using basic Mate commands such as Coincident, Parallel, Concentric, and Distance, we learned to position and constrain parts accurately, ensuring correct spatial alignment and realistic mechanical behavior. These constraints also helped us detect potential interferences and improve overall design reliability.

- We then explored advanced Mate tools, including Width, Symmetric, Path, and Limit Mates. These functions enabled dynamic mechanical simulations, replicating real-world movements such as sliding, rotation, and restricted motion between shafts, gears, and structural parts. Through these exercises, our team gained deeper insight into kinematic relationships and motion dependencies in complex mechanical systems.

- In addition, we learned to create and manage assembly drawings, incorporating exploded views, Bill of Materials (BOM), and annotations. We practiced defining section views and detailed callouts to clearly illustrate component structures and assembly procedures.

3. Application to Water Purifier Design

In the Eco Filter Project, these assembly and drawing tools were directly applied to our portable water purifier prototype.

- Basic Mates were used to align key components such as filter casings, inlet and outlet tubes, and the pump housing with precision.

- Advanced Mates simulated realistic motion between internal filters, connecting pipes, and mechanical joints to test fit and function before fabrication.

- The assembly drawings included detailed exploded views showing the relative positions of subcomponents, while the BOM table listed each part’s name, quantity, and material, providing complete documentation for production and maintenance.

4. Conclusion

This research stage significantly strengthened our ability to transition from independent 3D parts to a fully functional mechanical assembly. We mastered the use of Mates, motion simulation, and technical drawing documentation—core competencies in professional mechanical design. The process enhanced our precision, problem-solving skills, and spatial visualization, forming a strong foundation for real-world engineering applications.

5. Next Step

In the next phase, our team will advance to Simulation and Rendering modules in SolidWorks. These tools will be applied to analyze mechanical motion, evaluate stress distribution during operation, and create photorealistic renderings of the portable water purifier model for presentation and performance evaluation.