1. Objective

The objective of this stage is to apply fundamental sketching techniques in SolidWorks to design the structural components of a portable water purifier. This step marks the transition from basic interface familiarity to practical design application, carried out under the supervision of our instructor.

2. Summary of Learning

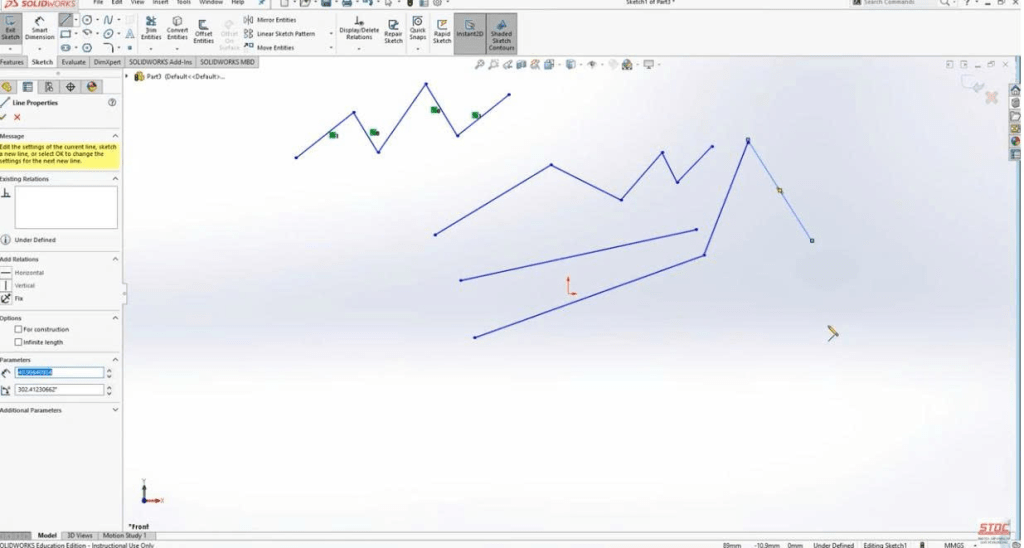

In this research phase, our team learned to create precise 2D sketches using the Basic Sketching Commands in SolidWorks. We began by selecting appropriate sketch planes—Front, Top, or Right—and utilized essential tools such as Line, Rectangle, Circle, and Arc to define basic geometries.

We then applied Smart Dimensions to specify exact measurements and Geometric Relationships (Parallel, Perpendicular, Tangent) to ensure that the sketches were fully constrained and geometrically stable.

Additional functions like Trim Entities, Offset Entities, and Mirror Entities were used to refine and optimize sketch structures. For instance, the Trim command allowed us to remove unnecessary segments, while the Mirror tool enabled the efficient creation of symmetrical shapes. Color indicators in SolidWorks (blue – under-defined, black – fully defined, red – over-defined) provided real-time feedback on sketch accuracy and definition.

3. Application to Water Purifier Design

These sketching techniques were directly applied to define the 2D profiles of key components, including the filter housing, connecting pipes, and base frame of the portable purifier. Accurate sketching ensured that each component would align properly during the 3D assembly stage and meet the mechanical and functional requirements of the purifier.

By consistently using geometric constraints and precise dimensions, our team established a uniform design standard, ensuring structural consistency across multiple parts before extrusion into 3D models.

4. Conclusion

This stage strengthened our team’s ability to develop accurate and well-constrained 2D sketches in SolidWorks. Mastering these basic sketching commands forms the foundation for creating detailed 3D models in subsequent phases. The skills gained in this step are essential for ensuring dimensional accuracy, geometric stability, and overall compatibility among components in the Eco Filter Project.

5. Next Step

In the next research stage, our team will proceed to Lesson 3: “Creating 3D Features in SolidWorks.”

→ The upcoming tasks will involve extruding and revolving sketches to generate solid models of the purifier’s main body, housing, and handle components.